CONCRETE POOL

Concrete for a pool that lasts

Concrete swimming pools can be adapted to suit all tastes and requirements. Thanks to our modular system, you can give free rein to your creativity and create your own traditional or made-to-measure pool! (Create a pool that suits you.)

As a specialist in concrete pools in the west of France (La Rochelle, Limoges, Brive-la-Gaillarde, Périgueux), Piscine Ambiances can help you design, build and maintain your pool.

Get ready to enjoy your concrete swimming pool for many years to come!

Whatever the manufacturing process used, we offer a ten-year guarantee.

The pool of your dreams

Give free rein to your imagination and creativity to create the swimming pool project that’s closest to your dreams, thanks to concrete pools. From the classic pool to the urban pool to the swim lane, there are many possibilities open to you.

When you choose a concrete pool, you’ll have a wide choice of ways to personalise your pool, which will bring the whole family together to satisfy both young and old. We’ve designed bottom shapes that combine comfort, conviviality and safety.

You can customise the shape of the pool, but also choose the steps for your concrete pool (double, compact, outdoor square, full access bench, etc.). Some models can be fitted with our patented AirSense balneotherapy system. You can also add our various innovations such as the SunWay, or our SmartCover immersed covers.

Recognised expertise

Concrete is the primary material used in the construction of traditional in-ground swimming pools. Its strength and solidity are well established.

With an in-house Research and Development department, we are constantly improving our manufacturing process. More than 12,000 concrete pools have been built in this way.

Our patented system of modular reinforced concrete walls is perfect for building straight or angular pools.

Concrete, the material of choice for swimming pool construction

Whatever the type of pool, concrete is very often used in its construction. Above-ground or semi-sunken pools, for example, are very often installed on a concrete invert to ensure stability. This is also the case for shell pools, which also require a concrete invert before the shell is built in.

The best-known manufacturing technique is still traditional masonry, in which the use of concrete is more than obvious. Once the breezeblocks have been installed, they are sealed together with concrete. Concrete is also used in the bottom of the pool for the invert.

There are many other ways of building in-ground pools, and they all use concrete in at least one stage of construction. These include the shotcrete technique, which uses reinforced concrete as the sole material for the structure of the pool. Once the hole has been dug, metal structures are installed and then covered with concrete. Once dry, the concrete is smoothed with a special coating that also makes the pool watertight.

Other pool builders use techniques based on plastic or polystyrene moulds that act as cinder blocks. Once the shape of the pool has been defined, these moulds are filled with concrete to form the structure of the pool. However, beware of the joints between the blocks, which can become weak points over time.

Discover our flagship concept

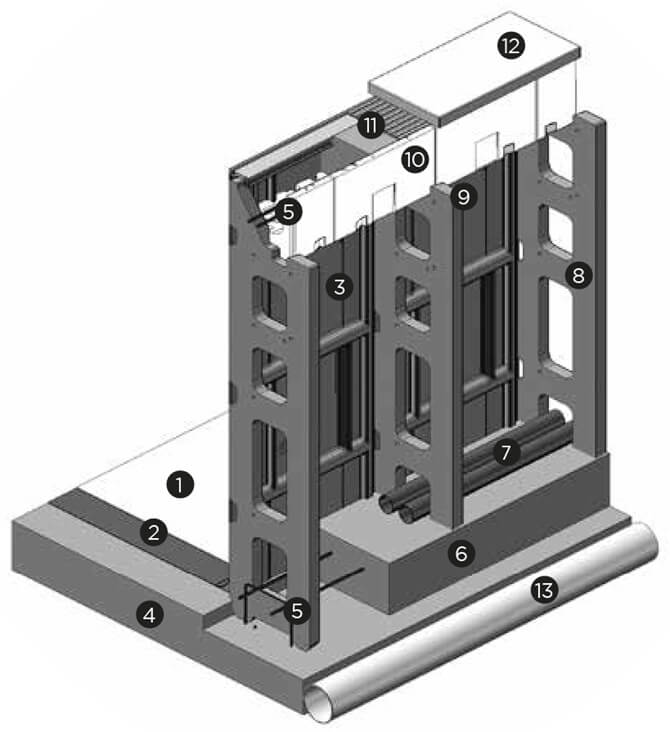

A guarantee of durability, the self-supporting structure withstands water pressure even when there is no backfill, as well as earth pressure when the pool is empty. The result: very high resistance. The structure is built by assembling modular concrete panels without bolting them together. Each panel weighs no more than 35 kg, making it easy to install. Thanks to its support reinforcements, this structure can also be used to support beaches. Two belts of reinforced concrete are cast in situ to form a single unit, ensuring the structure’s unalterable strength. This technique makes it possible to build bespoke concrete swimming pools.

At Piscine Ambiances, we have developed our own concrete-based construction system. We have devised and patented techniques that involve building concrete panels or elements that are then assembled together to build the pool. The pool is then waterproofed with a liner or reinforced PVC.

As you can see, all pool builders agree that concrete is the preferred material for pool construction, because its solidity makes it a perfect ally for the longevity of the works. At Piscine Ambiances, we understand this, which is why our construction processes use only concrete as the building material for the pool structure.

- Liner

- Thibaude

- Reinforced concrete panel

- Concrete slab

- Concrete steel

- Reinforced concrete ring beam

- Protected pipes

- Reinforced retaining wall

- Support for terrace

- Permanent formwork and expansion joint

- Upper ring of reinforced concrete

- Coping or SunWay

- Perimeter drain (if required)

* The formwork for a SunWay is wider for 60cm wide cladding.

Why prefabricated reinforced concrete walls?

All the concrete components needed to manufacture our swimming pools are prefabricated in France. The production workshop complies with strict specifications guaranteeing the quality of the concrete components (mix, reinforcement, drying and storage times and conditions, etc.). This process ensures that the concrete components are produced under optimum conditions, which has a significant impact on the strength of our pools.

We want to work locally, so that we can control both the quality of our products and supply times.

This positioning enables us to offer you a robust, attractive and durable process.

This construction system has the advantage of reducing construction times, because the concrete modules are already dry and robust. What’s more, unlike pools built using blocks (PVC or polystyrene) filled with concrete, our walls and struts have no weak points that could become brittle over time.

This construction system has nothing but advantages: robustness thanks to reinforced concrete, time-saving during construction, made-to-measure concrete pools, easy access to sites with narrow exteriors, etc.

To ensure that our prefabricated modules are held in place perfectly, our structural work teams pour a floor slab and create a concrete chain-link at the top, so that all the elements are held together.

Thanks to our patented innovation (SunWay∂), the top ties also hold the coping stones in place. This process holds the coping directly to the structure around the pool, eliminating any risk of movement over time due to ground settlement.

Our manufacturing process has been tried and tested on all types of soil, whatever the configuration of the site.

The stages in building a concrete swimming pool

FAQ concrete swimming pool

1. What are the advantages of a concrete swimming pool?

Strength and durability

A reinforced concrete pool offers strength and durability, guaranteeing a structure that is resistant to weather and ground movement. Reinforced concrete is particularly resistant to bad weather, humidity and temperature variations, reducing the need for maintenance and repairs. This type of pool can last for several decades without deteriorating.

Added value for your property

Investing in a concrete pool increases the value of your property. Its durability and superior aesthetics make it a major asset.

Renovation and upgradability

Concrete pools offer remarkable flexibility when it comes to renovation. You can change the shape, add new equipment or modernise existing finishes.

Aesthetics and customisation

Concrete offers a refined aesthetic finish. The possibilities for decoration are vast, allowing you to create a unique, made-to-measure ambience for every homeowner.

2. How long does it take to build a concrete pool?

The time taken to build a concrete swimming pool varies from one pool builder to another, mainly because of the manufacturing process.

A concrete pool requires structural work to be carried out on site, independently of the earthworks. The structural work is directly affected by the nature of the soil and the weather, which can delay the time needed to complete the work.

The construction of a concrete pool will take longer than for other processes such as shell pools, mainly because of the drying time. However, concrete will ensure that your pool lasts longer, and will also make it easier to renovate in several decades’ time.

Thanks to our process of manufacturing pre-designed concrete walls, Piscine Ambiances is able to reduce pool construction times to 15 days, or 3 weeks if weather conditions permit.

These times are average estimates and may vary depending on the specifics of each project, the terrain and access. Careful planning and the choice of experienced professionals are essential to ensure quality construction on schedule.

3. What’s the difference between a concrete pool and a shell pool?

The choice between a concrete pool and a shell pool depends on your specific needs, your budget, how quickly you want your pool to be ready, and the level of customisation you want. Concrete pools offer unlimited customisation and exceptional durability. Very strong and durable. Reinforced concrete gives your pool exceptional resistance to the elements and to ground movement.

Shell pools, on the other hand, offer a quick, less expensive solution, but with a shorter lifespan due to the strength of the materials (fibreglass or polyester) and the renovation difficulties that some models can present.

4. Can I customise the shape and size of my concrete pool?

A concrete swimming pool is generally 100% customisable, depending on the manufacturing process. The pool is built on site by pouring concrete into formwork or by assembling reinforced concrete walls according to the manufacturing process used by Piscine Ambiances, a patented process.

A made-to-measure pool: Concrete pools offer a much wider range of shapes than shell pools. You can also choose the size and depth. Each pool is unique and built to the customer’s specifications.

A long-lasting pool: Very strong and durable, reinforced concrete gives your pool exceptional resistance to bad weather and ground movement. This extends the life of your pool. Like any building, your pool will one day need to be renovated, but it’s much easier to renovate a reinforced concrete pool than a shell pool. Generally, all that’s required is a new coating and a new waterproofing membrane.

A customisable pool: the concrete pool can be lined with any type of waterproofing (liner, reinforced PVC, 3D Touch), in a wide variety of colours and looks (natural stone, lagoon, deep water, tropical, etc.). So you’ll have the choice of personalising your pool to suit your desires and your environment.

5. How do I maintain a concrete swimming pool?

Regular maintenance of a concrete pool is essential to ensure its durability, aesthetic appearance and water quality. Here are the key steps to maintaining your concrete pool properly.

Whether your pool is made of concrete or not, you’ll need to clean it and the water regularly. If your pool is located outdoors, debris, leaves and pollen will settle on the surface of the water, so you’ll need to remove most of it with a landing net and leave the rest to your filtration equipment. Thanks to your pump, coupled with the passage of the robot, your bathing water will be free of all debris.

6. Do concrete swimming pools require frequent renovation?

Having a concrete swimming pool is a guarantee of peace of mind when you work with a reliable pool builder with solid experience. You should also make sure that your pool builder is a member of the Fédération des Professionnels de la Piscine, for added reliability.

Like any building, a concrete swimming pool will need to be renovated to extend its life and ensure that it runs smoothly. A pool built in concrete will require renovation much later than other processes. What’s more, a concrete pool is easier to renovate than a shell pool, for example. Concrete can be re-coated and re-waterproofed for many years of use.

7. What are the signs that my concrete pool needs repair?

There are several signs that it’s time to think about renovating your concrete swimming pool. Don’t panic, if you have the right advice and support, this step is an opportunity to give your pool a complete makeover, modernise it, make access more practical and put it back at the heart of your home.

Over the decades, like any building, your pool will change, both in terms of the ground it stands on and the materials it’s made of. Your pool, which is usually located outdoors, is also subject to weather conditions (cold winters, hot summers, etc.) that affect the materials used.

After several years of use, you may notice that your liner is coming undone, affecting the watertightness of your pool, or that nozzles are coming loose, causing water loss. In more extreme cases, you may see cracks due to ground movement.

If you notice these signs, it’s high time to consider renovating your pool. To do so, call in an experienced pool specialist who has already worked on this type of project. There’s nothing trivial about renovating a swimming pool, and you need to approach the whole project as a whole, analysing the various parts and equipment that make up your pool in order to draw up an inventory (structural work, waterproofing, hydraulics, etc….). It’s essential not to overlook any detail if you want to ensure that your renovation is meticulous and long-lasting.

We remind you that regular maintenance of your pool will help prolong its life and postpone the final stage of renovation.

8. What are the annual maintenance costs for a concrete swimming pool?

Whether you have a concrete pool or one made using another method, the cost of maintaining your pool will be similar. What influences the budget is the way your water is treated, i.e. whether you have a pool treated with salt by electrolysis or whether your pool is treated with chlorine.

Salt pool

Pool maintenance involves a number of variable costs, including electricity for the equipment, chemical treatments and water top-ups.

The minimum equipment required for a salt pool is a filtration pump and an electrolyser. A variable-speed pump is preferable, as it will consume less energy. For a standard-sized 8×4 pool, we estimate the cost of electricity at around €160. In addition, you’ll need a few water treatment products such as shock chlorine or flocculant, which will cost around €70, and lastly, you’ll probably need to top up the water at the beginning of the season and throughout the season, at a cost of around €50.

Your salt pool will cost you between €250 and €400, excluding equipment such as brooms, sponges, etc. and excluding operations linked to wear and tear on your pool.

Chlorine pool

For a chlorine pool, the electrical costs are mainly associated with the filtration pump, similar to those of a salt pool, about 160 euros per year. However, chemical treatments are more expensive, with annual chlorine expenditure of up to 200-300 euros. The water requirements for a chlorine pool are similar to those of a salt pool, only the size of the pool and the type of cover affect this factor. Maintenance is often more expensive for a chlorine pool, estimated between 400 and 600 €, compared to a salt pool.

In addition, maintenance contracts may be offered by some pool professionals, such as Piscine Ambiances, ensuring a long-term for your pool and tranquility throughout the season.

Our latest news

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.